03

2024-04

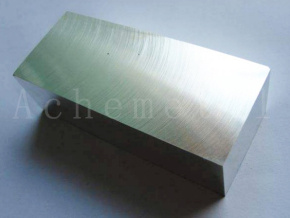

TZM block is an advanced material with excellent performance.

TZM blocks, also known as thermo-graphite, are advanced materials with exceptional performance. They are transformed from graphite into a material with excellent electrical and thermal conductivity through a special heat treatment process. Due to their unique properties, TZM blocks are increasingly used in various industries, including but not limited to semiconductor manufacturing, aerospace, and high-performance electronic devices.

The main characteristics of TZM blocks are as follows:

High thermal conductivity: TZM blocks have extremely high thermal conductivity, making them outstanding in applications that require rapid heat dissipation, such as heat sinks for high-performance computer chips.

Good electrical conductivity: As conductors, TZM blocks provide stable current transmission, suitable for strict electrical connections and heat dissipation devices.

High-temperature stability: TZM blocks can maintain stability at extremely high temperatures, making them ideal for applications such as spacecraft and jet engines.

Corrosion resistance: Due to the chemical inertness of graphite itself, TZM blocks can resist corrosion from most acids and bases, making them suitable for use in harsh environments.

Mechanical strength: Specially treated TZM blocks possess high mechanical strength, capable of withstanding high pressure and impact.

To manufacture TZM blocks, graphite material must undergo pyrolysis treatment at high temperatures. This process requires precise control of temperature and environmental conditions to ensure the quality of the final product. Additionally, the processing of TZM blocks requires specific techniques and equipment to ensure the desired dimensional accuracy and surface finish.

For engineers, when selecting TZM blocks as component materials, the following factors need to be considered:

Operating environment: Whether exposed to high temperatures or corrosive environments;

Performance requirements: Specific needs for electrical conductivity, thermal conductivity, and mechanical strength;

Cost-effectiveness: Whether TZM blocks have a cost advantage compared to other high-performance materials.

In practical applications, such as in the semiconductor industry, TZM blocks can be used as thermal management components in the wafer processing process. In the aerospace field, they can be used in parts of aircraft engines to improve fuel efficiency and reduce weight. In the power industry, TZM blocks can be used to manufacture high-efficiency electrical connectors and circuit breakers.

In summary, TZM blocks provide an important material solution for modern industry with their excellent thermal and electrical conductivity, combined with high-temperature stability and good mechanical properties. Whether in improving energy efficiency, enhancing product performance, or maintaining reliability in extreme environments, TZM blocks demonstrate great potential and application value. With continuous technological advancements and innovations, TZM blocks will play an increasingly critical role in the future of materials science and engineering.

TZM block

Next Page