SERVICE AREA

Service areas

Aerospace

In the field of aerospace, tungsten wire is used for heating elements of high-temperature components of aero-engines and electrodes of spacecraft power supply systems due to its high melting point, high density, high strength and excellent high temperature stability to ensure the operation of equipment in extreme environments. Molybdenum wire has high melting point, low thermal expansion coefficient and good thermal conductivity and electrical conductivity, and is applied to the throat lining of rocket engine nozzle and the thermal protection parts of aircraft wing leading edge to maintain the normal operation of the structure under high temperature and high speed.

Photovoltaic industry

In the photovoltaic industry, tungsten wire is used for heating elements of high-temperature sintering furnaces for battery chip production to improve photoelectric conversion efficiency, and can also be used as special connection parts for components to ensure electrical connection reliability. Molybdenum wire is mainly used in silicon wafer cutting to reduce loss and improve cutting quality. It can also be used as a new type of battery back electrode conductive skeleton material to enhance battery performance and promote the development of photovoltaic power generation technology.

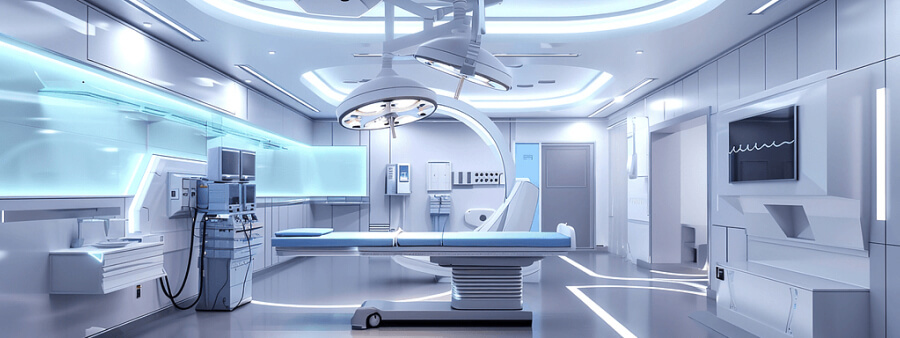

Medical and Health

In medical treatment, tungsten wire is often used in X-ray tube filament to generate X-ray for diagnosis, and is also used as electrode of minimally invasive surgical instruments to realize accurate electrical operation of tissues. Molybdenum wire is used for medical implant components due to its good biocompatibility and corrosion resistance, and can also be used as conductive element of sensor of medical testing equipment to provide accurate data support for testing.

nuclear industry

In the nuclear industry, tungsten wire can manufacture reactor control rod assemblies and high-temperature heating equipment components due to its high melting point and radiation resistance, accurately control nuclear reactions and ensure the safety of the treatment process. Molybdenum wire relies on good mechanical and radiation resistance and is used for control rod guide tubes and some special core assemblies to stabilize the operation of control rods and reduce interference with neutron flux, thus helping the nuclear reaction to advance effectively.

Semiconductor

In semiconductor manufacturing, tungsten wire is used as a heating element of chemical vapor deposition equipment to ensure the quality of thin film growth, and also serves as a chip test probe material to ensure test signal transmission. Molybdenum wire is mainly used for sputtering target binding material to ensure sputtering uniformity, and is used as heating wire for special heating process to improve semiconductor material performance and promote semiconductor device manufacturing process.